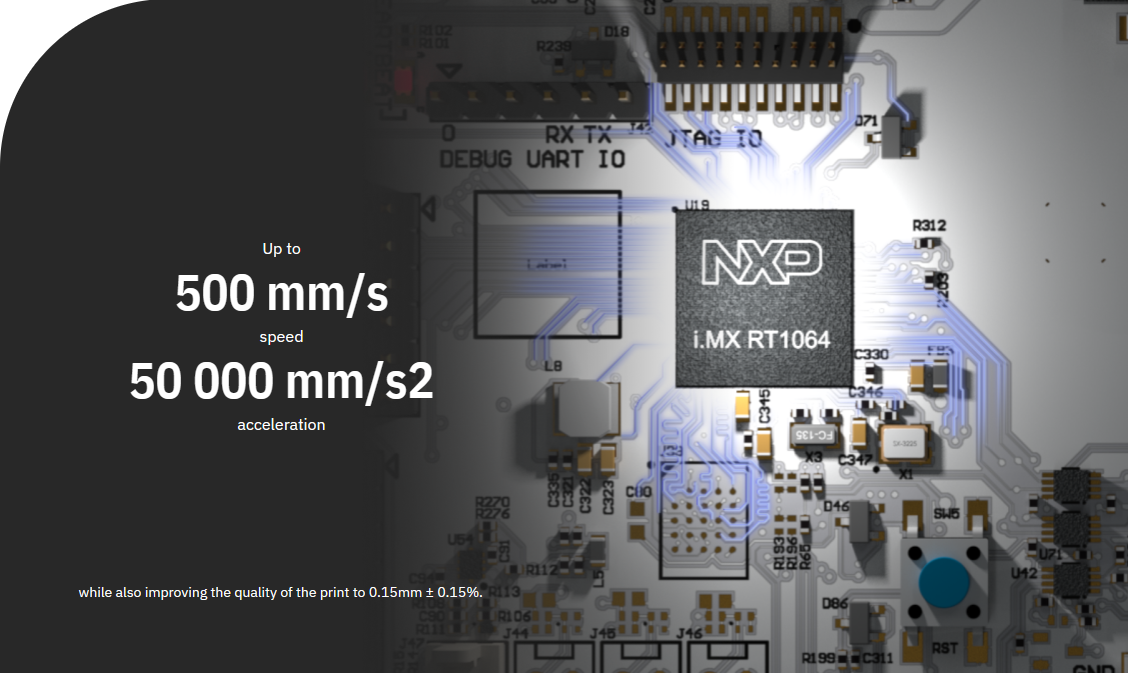

Blazing productivity. |

The UltiMaker Cheetah motion planner

Unlock new levels of efficiency with the new UltiMaker Cheetah motion planner, redesigned high flow print cores, built-in accelerometer, new feeder system, and improved firmware. |

|

All the uptime in the world. |

Automatic material handling

Designed to be left unattended, the Material Station allows the UltiMaker S8 to 3D print longer – day or night. Loading material into the Material Station takes seconds – not minutes. Simply open the door and drop the spool into a bay. During a print, any spool not in use can be switched out. |

|

3D print more materials. More easily. |

Hassle-free storage

Every spool is kept below 25% relative humidity, making it easy to realize more 3D printing applications with almost any combination of polymers and abrasive composites. Each of the Material Station's material bays have NFC readers and reinforced prefeeders for integration with UltiMaker Cura and Digital Factory. |

|

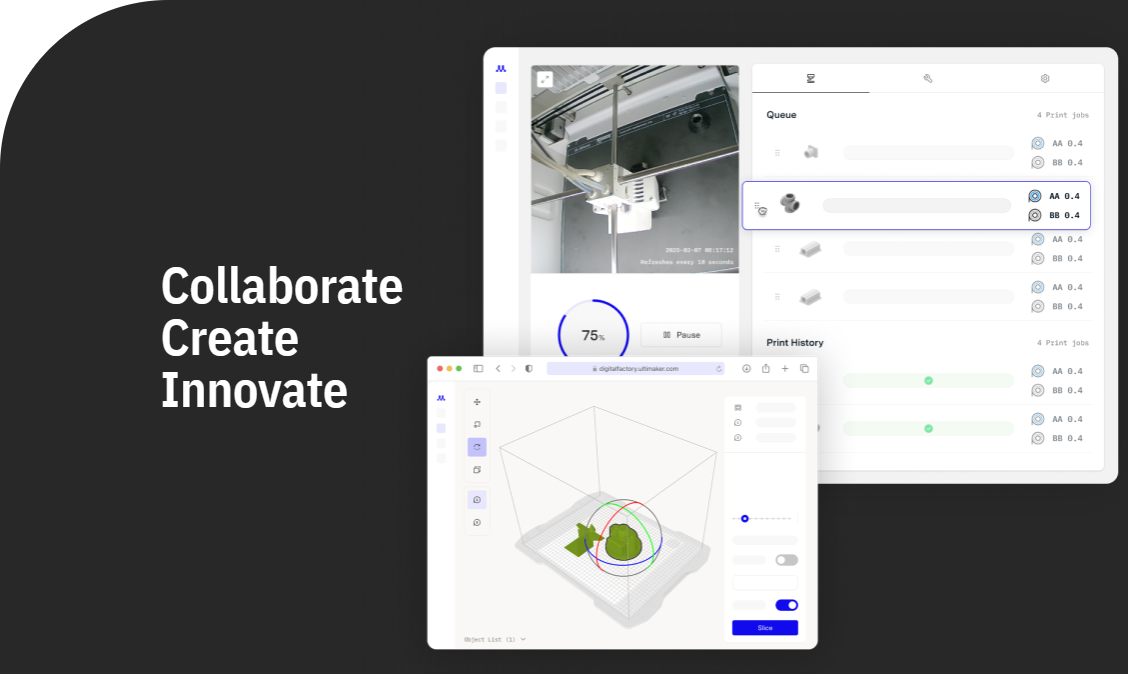

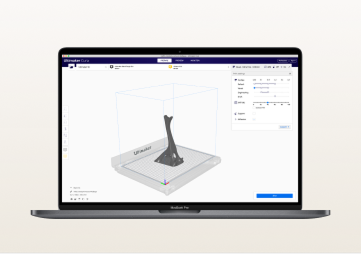

Digital Factory |

The only 3D printing software you will ever need

Digital Factory is designed to streamline every step of your 3D printing workflow. Scalable for any team or enterprise, Digital Factory makes managing your 3D printing projects easier, faster, and more collaborative. |

|

Advanced hardware and software security features built-in for professional use. |

Advanced hardware and software security features built-in for professional use.

Designed and built in Europe, the UltiMaker S8 is equipped with comprehensive security features, offering peace of mind for professionals in engineering and manufacturing. From secure hardware to advanced firmware, every aspect is designed to protect your intellectual property and ensure safe operation. |

|

|

|

|

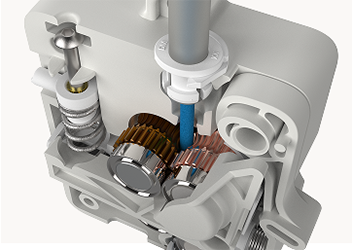

Updated feeder system

New hardened feeder module design inherited from Factor 4 for improved grip and better material control at high speeds. |

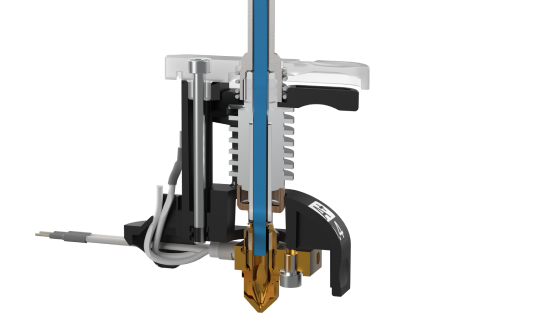

Dual high flow print cores

The dual extrusion design works together with software and firmware features to allow you to combine any 2 materials no matter how different they are, with low material waste and high reliability. |

Integrated EPA filter

Independently tested to remove up to 95% of ultrafine particles to increase air quality and peace of mind. The fully enclosed build chamber also boosts print quality. |

|

|

|

High flow print cores

The new AA+ and CC+ print cores, exclusive to the UltiMaker S8, have a new quad-chamber design that allows for 2.5x more flow and also help with regulating the pressure in the print head for cleaner prints. |

Flexible build plate

Skip using glue and remove parts effortlessly with the PEI-coated flexible build plate. Its patent-pending design uses 25 magnets and 4 pins for perfect alignment – reducing the time spent using the S8 and increasing productivity. |

Cura integration

Access the UltiMaker Cura features that speed up your workflow and increase print success – like intent profiles, easy remote printing, and more. |

UltiMaker S8 Pro Bundle Specs |

Dimensions |

Build volume |

330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) |

| Assembled dimensions |

W 495 x D 585 x H 800 mm (W 19.5 x D 23 x H 31.5 inches) |

| Print technology |

Fused Deposition Modeling (FDM) |

| Compatible filament diameter |

2.85 mm |

| Weight |

49.1 kg (92.4 lbs) |

| Maximum power output |

500 W |

| Dimensional accuracy |

± 0.15 mm ± 0.15% feature nominal length* |

| Extrusion flow |

Up to 35 mm3/s |

| XY speed, acceleration, jerk |

Up to 500 mm/s, up to 50.000 mm/s2, up to 100.000.000 mm/s3 |

Printer properties |

Layer resolution |

0.25 mm nozzle: 150 - 60 micron, 0.4 mm nozzle: 200 - 20 micron, 0.6 mm nozzle: 300 - 20 micron, 0.8 mm nozzle: 600 - 20 micron |

| XYZ resolution |

6.9, 6.9, 2.5 micron |

| Feeder type |

Dual-geared feeder, reinforced for composite materials |

| Display |

4.7-inch (11.9 cm) color touchscreen |

| Print core replacement |

Swappable print cores |

| Print head |

Dual extrusion print head with an auto-nozzle lifting system, swappable print cores, and flood detection. |

| Nozzle diameters |

0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm |

Operation parameters |

Filter technology |

Replaceable EPA filter |

| Air extraction rate |

1 - 50 m³/h (35 m³/h nominal rate for most materials at 23 °C) |

| Nozzle temperature |

180-280 °C |

| Nozzle heat-up time |

< 2 minutes |

| Operating sound |

< 51 dBA |

| Build plate leveling |

Advanced active leveling with more accurate inductive sensors |

| Build plate |

PEI-coated flexible steel build plate |

| Build plate heat-up time |

< 5 minutes (from 20 to 60 °C) |

| Operating ambient temperature |

15 - 32 °C (59 - 90 °F) |

| Non-operating temperature |

0 - 32 °C (32 - 90 °F) |

Ecosystem |

Supplied free software |

UltiMaker Cura – print preparation software UltiMaker Digital Factory – All-in-one cloud-based print, printer and user management software |

| Supported OS |

MacOS, Windows, and Linux |

| Plugin integration |

SolidWorks, Siemens NX, Autodesk Inventor |

| Supported file types |

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP |

| File transfer |

Wi-Fi (2.4 & 5 GHz), Ethernet, USB |

Safety and compliance |

Certification |

CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use |

|

More information |

Learn more about UltiMaker S8 safety and compliance. |

When you buy an UltiMaker S8 Pro Bundle you will receive:

- UltiMaker S8 3D Printer

- UltiMaker S8 Material Station

Accessory Items:

- Flexible build-plate

- Spool holder with material guide

- Power cable

- Ethernet Cable

- USB Stick

- Print core CC+0.4

- Print core AA+0.4

- XY Calibration Sheet

- Anti-slip rubber feet (4x)

Digital Factory

- 60 day Trial

- UltiMaker Library - Print your first part from Digital Factory

Tools & maintenance:

- Nozzle Cover (3x)

- Oil

- Grease

- Hex screwdriver 2 mm

Materials

- Spool PET-CF 750g

- Spool TPU 95A 750g

- Air manager Filter