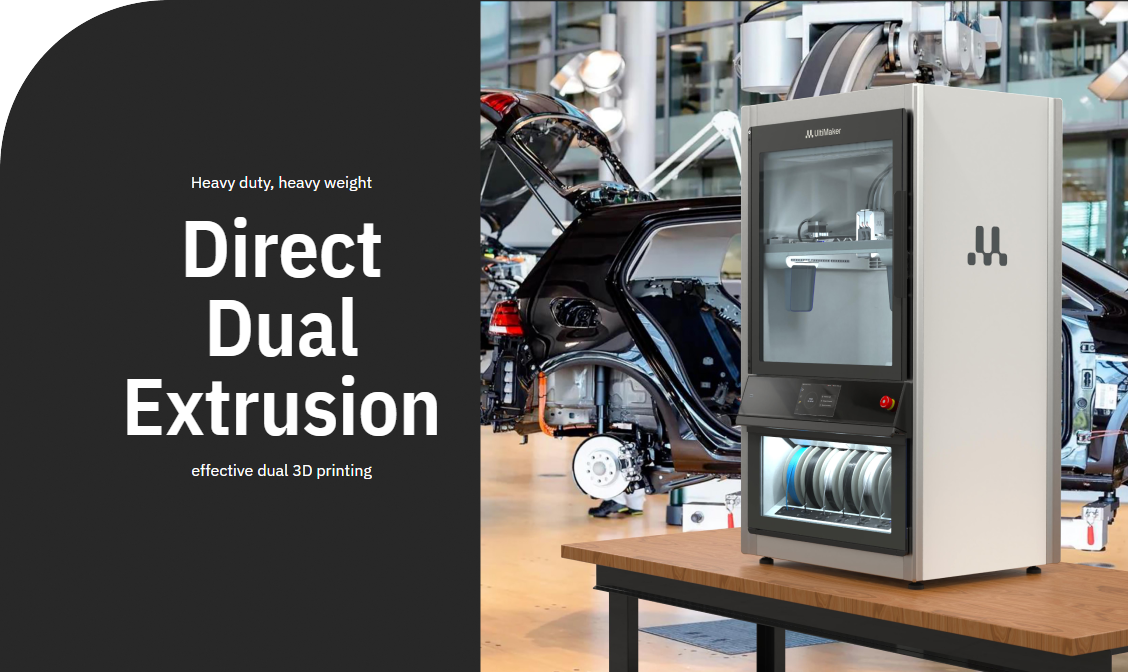

Built for the factory floor. |

The seamless, powerful upgrade that your production workflows demand.

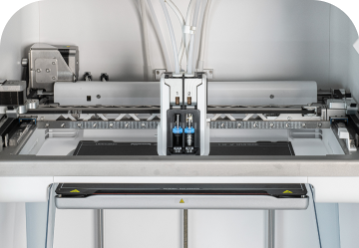

Factor 4 elevates manufacturing with its triple-insulated build chamber and direct dual extrusion. The automated material handling system maintains filament quality. And the robust, temperature-controlled design ensures consistent production output also on complex and challenging designs. |

|

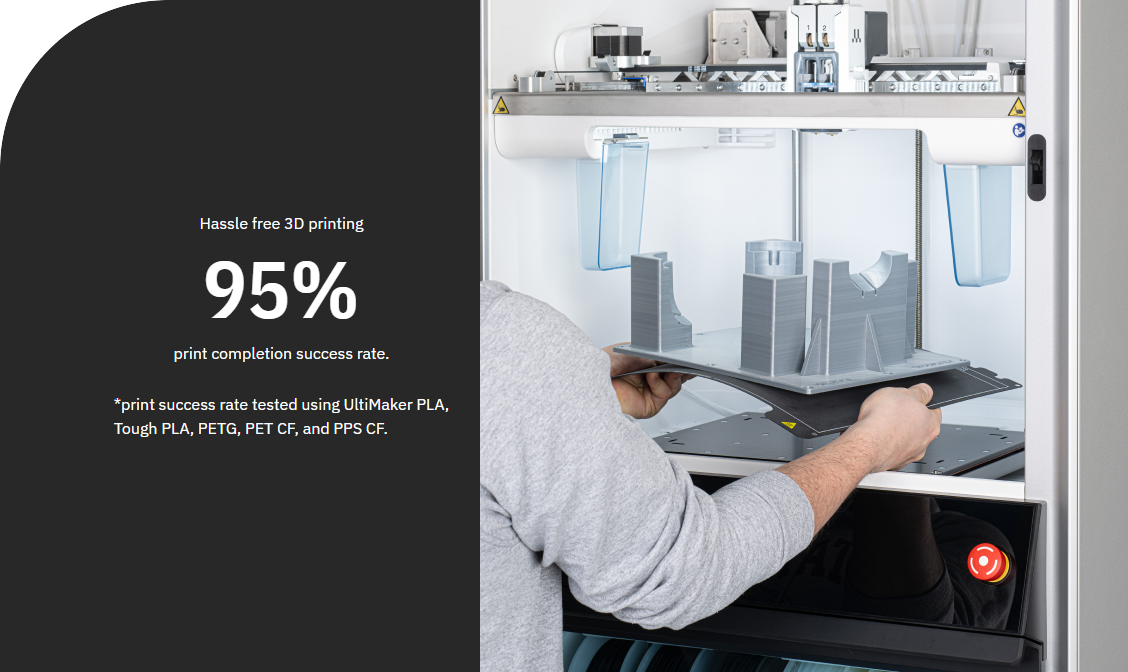

Reliability, repeatability and validation. |

High quality results. Every time. Anywhere.

Achieve the highest print accuracy of any UltiMaker printer – even at high resolution on small design features. These will achieve a dimensional accuracy of ± 0.2 mm + ± 0.2% of feature nominal length over the full build plate and across multiple printers.* |

|

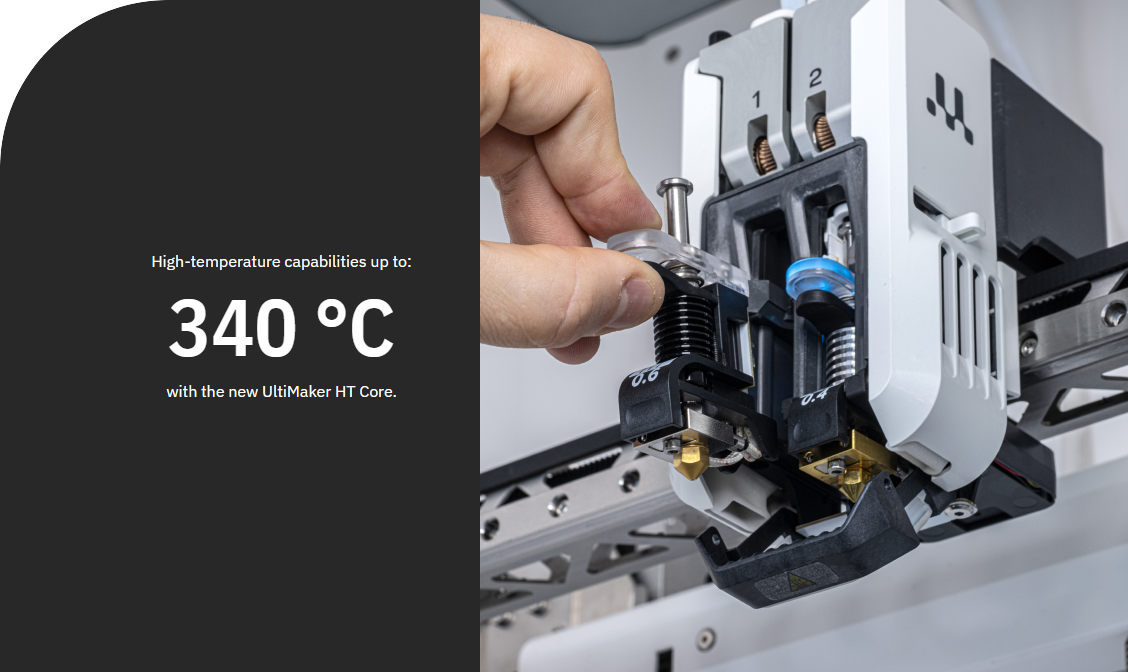

Achieve more with FDM 3D printing. |

Direct drive extrusion for flexible materials.

The Factor 4 excels at quickly switching from 3D printing highly flexible materials all the way to strong composites, like UltiMaker PPS CF. Its H-bridge gantry and direct drive head enable rapid dual material printing. |

|

High quality. Every time. Anywhere. |

Success with every 3D print.

Factor 4 makes it possible to additively produce & deploy structural integrity verified parts across different locations. The low variance, less than 10%, in extrusion rate and mechanical properties batch after batch, part after part is a combination of the H-bridge gantry, closed loop feed control, and uniformly controlled build plate temperatures – with a maximum variation of 2 °C across the X and Y axes. |

|

A future-proof investment. |

Versatility and quality that translates to fast ROI.

Regular updates ensure that your Factor 4 will evolve over time – far beyond the 12 to 18 months it will take to achieve return on investment. The 3D printer's modular build allows our global support network to quickly replace parts, minimizing downtime. |

|

Built on more than 13 years of UltiMaker legacy – dedicated to innovation, accessibility, and openness. |

Integrated HEPA filter

Independently tested to remove up to 95% of ultrafine particles to increase air quality peace of mind. The fully enclosed build chamber also boosts print quality. |

|

Onboard structural integrity validation

After every print job, receive an in-depth report on extrusion parameters deviations from nominal values, their locations, and their severity in the 3D model. |

|

|

|

Automated material handling with low humidity storage

Automatic pre-loading and spool switching (up to 6) with RH < 15% on any external conditions. |

Emergency stop button

A conspicuous red STOP button ensures easy and safe operation should there be a need to immediately halt printing. |

|

|

|

7-inch capacitive touchscreen

Mounted higher to give a better view of the first layers when remote monitoring. Monitor your print in high resolution remotely via UltiMaker Digital Factory. |

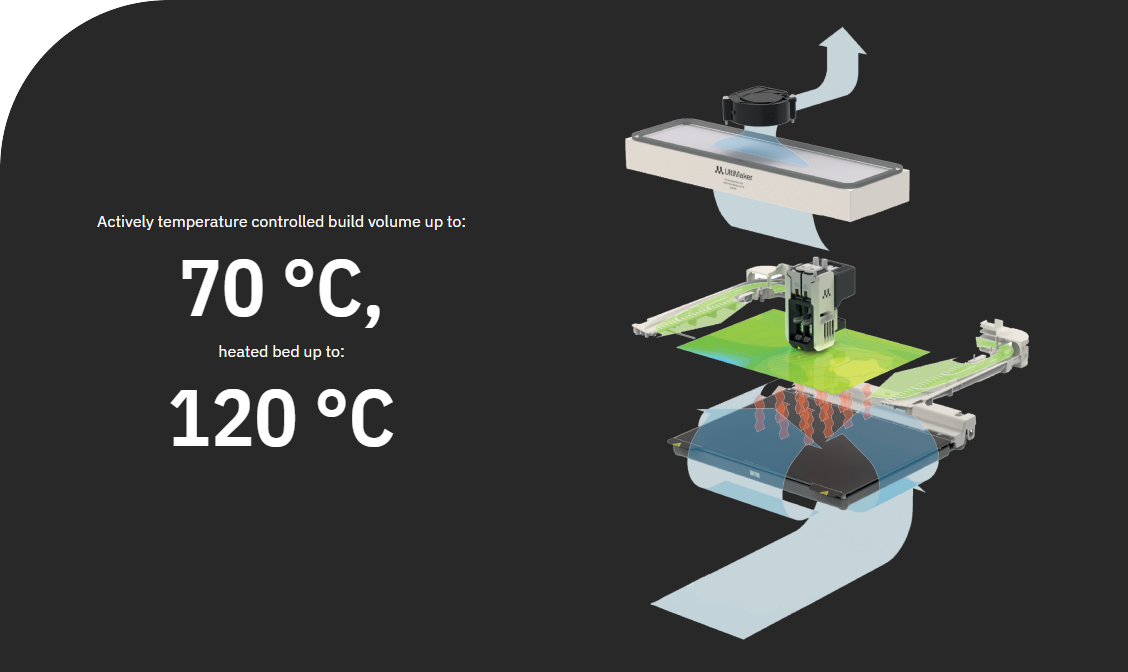

H-bridge Gantry

H-bridge gantry and direct drive head enable rapid dual material printing. Factor 4 is capable of reaching up to 340°C on its print cores, 70 °C on the print chamber and 120 °C on its heated bed. |

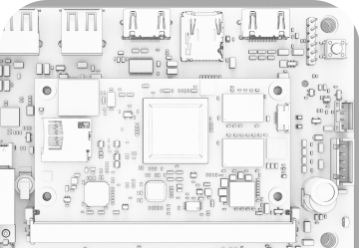

Always up to date.

With dual onboard processors, there is plenty of computing headroom for planned and even unplanned future updates. |

UltiMaker Factor 4 Specs |

Dimensions |

Build volume |

330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) |

| Assembled dimensions |

695 x 605 x 1287 mm (27.5 x 24 x 51 inches) |

| Print technology |

Fused Deposition Modeling (FDM) |

| Compatible filament diameter |

2.85 mm |

| Weight |

120 kg (265 lbs) |

| Maximum power output |

600 W |

Printer properties |

Layer resolution |

60 – 400 microns (depending on print core nozzle size and selected print profile) |

| XYZ resolution |

6.25, 7.8, 2.5 microns |

| Feeder type |

Dual-extrusion, direct drive print head and swappable print cores |

| Display |

7 inches interactive touchscreen (resolution 1024 × 600 px) |

| Print core replacement |

Swappable print cores |

| Print head |

Dual extrusion print head with an auto-nozzle lifting system, swappable print cores, and flood detection. |

| Nozzle diameters |

0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm |

Operation parameters |

Filter technology |

Replaceable HEPA H13 filter |

| Nozzle temperature |

180 - 340 °C |

| Build plate |

PEI-coated flexible steel build plate |

| Operating ambient temperature |

18 - 30 °C (64 – 86 °F) , Humidity: 30 – 70% RH |

| Non-operating temperature |

5° – 40 ºC (41 – 104 °F) , Humidity: 20 – 90% RH |

Ecosystem |

Supplied free software |

UltiMaker Cura – print preparation software UltiMaker Digital Factory – printer management software |

| Supported OS |

MacOS, Windows, and Linux |

| Plugin integration |

SolidWorks, Siemens NX, Autodesk Inventor |

| Supported file types |

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP |

| File transfer |

Wi-Fi (2.4 & 5 GHz), Ethernet, USB |

Safety and compliance |

More information |

Learn more about UltiMaker Factor 4 safety and compliance. |

|

Safety Features |

Red Stop Button for motion & heat sources immediate stop Open Door Sensor for motion and extrusion pausing. |

|

Warranty Period |

12 months Limited Warranty |

When you buy an UltiMaker Factor 4 you will receive:

- UltiMaker Factor 4 3D Printer

Accessory Items:

- Power Cord

- 2x AA Print Core - 0.40mm

Documentation

- Quick Start Guide

- Safety & Warranty Booklet

Tools & maintenance:

- Wire Cutter

- USB Stick

- Safety and Warranty Info

- Quick Start Guide

Materials

- 2x Spool of TPLA Filament - Black